Ringsend Wastewater Treatment Ultrafiltration & Reverse Osmosis Plant

Dublin, IrelandThe Ringsend WwTW consumes large quantities of potable grade water (mains supply water) to operate its many industrial processes with a combined usage in excess of 650m3/day.

Recycled final effluent is also used in some areas of the plant, most commonly for wash-down operations. In 2011, Celtic Anglian Water (CAW) in partnership with Dublin City Council, carried out a feasibility study to assess the economic and technical merits of recycling final effluent to reduce the demand on mains supplied water. The Study concluded that final effluent subjected to Ultra-filtration and Reverse Osmosis treatment could replace much of the potable water used on site.

The Delivery of the Ultra-filtration & Reverse Osmosis Plant

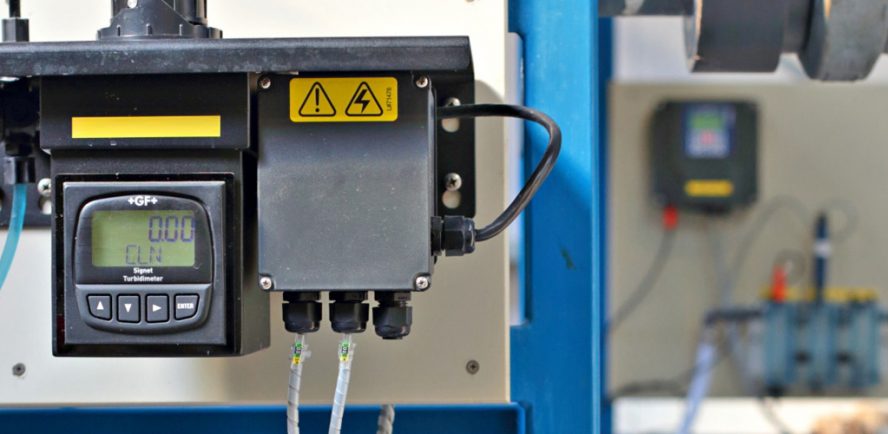

As a result of the findings of the Feasibility Study, CAW undertook the contract to design and build the Ultra-filtration & Reverse Osmosis Plant for the treatment and re-use of final effluent at the Ringsend WwTW.

Under the contract, CAW was responsible for the design, supply, installation and commissioning of the Ultra-filtration & Reverse Osmosis Plant, including all civil engineering and building works.

The process involves extracting final effluent from the outfall channel using wash return water pumps to pass the effluent through ultrafiltration membranes producing a permeate water which is chlorinated and then pumped through a dedicated network of clean water site distribution pipework and storage buffer / break tanks. Some of this chlorinated water is then passed through a further stage of Reverse Osmosis treatment and pre-filtration before being fed into the on-site steam generating boilers. The quality of the reverse osmosis water is such that it reduces the blowdown cycle time on the boilers compared to boilers fed on potable water.

The delivery of the Ultrafiltration & Reverse Osmosis Plant was completed by CAW over an eleven month period, January – November 2012 at a cost of c.€1m.

The Plant currently provides 550 m3/day reducing the requirement for mains supplied water by 90%.

Sustainable Development

CAW is strongly committed, not just at the Ringsend WwTW but company-wide, to sustainable development and the delivery of best practice where it involves the prudent re-use of waste streams and waste resources, and the protection of the environment. Within this commitment lies the recognition that water is one, if not the most valuable, resource on the Earth.

In executing the delivery of the Ultra-filtration & Reverse Osmosis Plant at Ringsend WwTW, CAW has reduced the Works demand for mains supplied water by over 90%, saving c.550m3/day, thus making a significant contribution to the conservation of water through the implementation of a sustainable development based on the recovery of potable grade water from the final effluent stream.

Public Health and Health & Safety

Prior to the delivery of the Ultra-filtration & Reverse Osmosis Plant at Ringsend WwTW, significant volumes of final effluent were being used for general wash-down operations throughout the site the quality of which could have potentially presented risks to the health of operations staff on the site. As a result of the installation of the Ultra-filtration & Reverse Osmosis Plant, potable grade chlorinated water is now used for wash-down purposes, thus mitigating any associated health risks for site staff.